Johns Manville PVC Systems

Built to withstand the test of time, Johns Manville's PVC was made to resist the toughest weather conditions and chemicals.

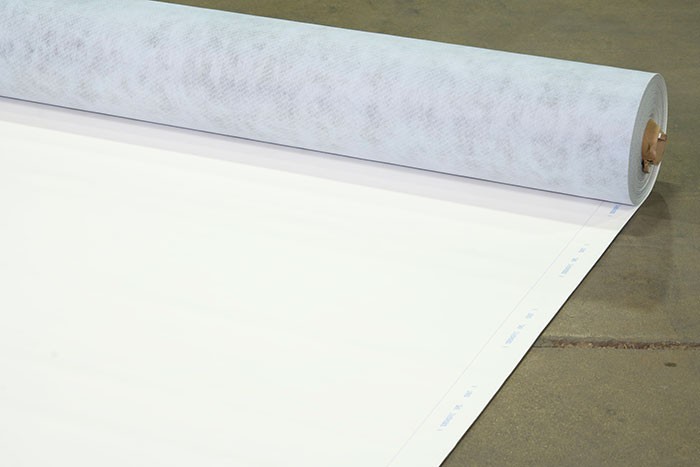

JM PVC FB with DuPont Elvaloy KEE Polymer

Meets the requirements of ASTM D 4434, Type III

Advanced Solid Phase Polymer Formulation: Uses the optimal amount of DuPont™ Elvaloy® KEE (Ketone Ethylene Ester) polymer to ensure plasticizer retention, extend roof life, and to reduce maintenance costs.

Patented Aramid-Reinforced Edge: Aramid fiber is woven into the fastening side of all full rolls of PVC membrane.

Spunbond 3.8 oz. Polyester Fleece Back Mat: Interlocking, multiplelayer, uniformly arranged continuous filament strands are needle punched with thousands of barbed needles, creating an extremely durable, strong yet light and flexible protection layer.

Non-wicking Reinforced Polyester Scrim: Our fully integrated manufacturing process adds tensile strength and toughness. Due to the non-wicking edge sealant is not required.

Excellent Chemical Resistance: JM PVC is inherently resistant to oils, air conditioning coolants, fuels and grease.

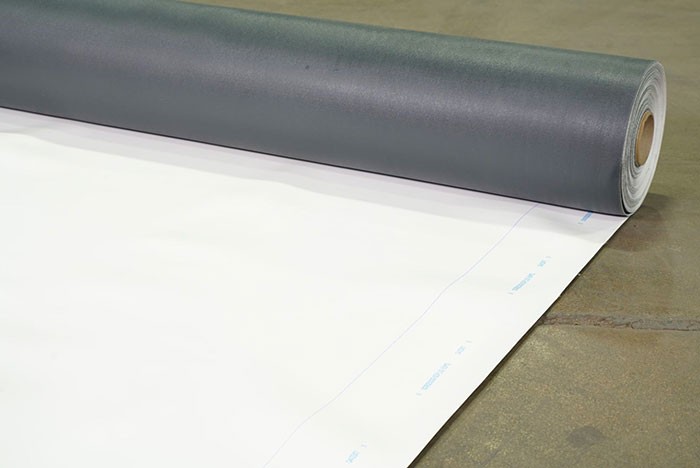

JM PVC SD Plus

Meets the requirements of ASTM D 4434, Type III

Non-wicking Reinforced Polyester Scrim: Our fully integrated manufacturing process adds tensile strength and toughness. Edge sealant is not a requirement for cut edges.

Excellent Chemical Resistance: JM PVC is inherently resistant to oils, air conditioning coolants, fuels and grease.

Energy Savings: The white membranes provide exceptional reflectivity and emissivity for energy savings.

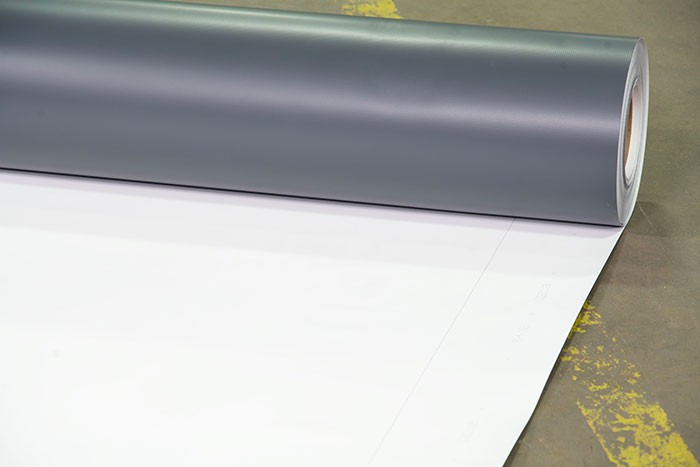

JM PVC with DuPont Elvaloy

Meets the requirements of ASTM D 4434, Type III

Advanced Solid Phase Polymer Formulation: Uses the optimal amount of DuPont™ Elvaloy® KEE (Ketone Ethylene Ester) polymer to ensure plasticizer retention, extend roof life, and reduce maintenance costs.

Patented Aramid-Reinforced Edge: Aramid fiber is woven into the fastening side of all full rolls of PVC membrane.

Non-wicking Reinforced Polyester Scrim: Our fully integrated manufacturing process adds tensile strength and toughness. Due to the non-wicking edge, sealant is not required.

Excellent Chemical Resistance: JM PVC is inherently resistant to oils, air conditioning coolants, fuels and grease.

Energy Savings: White, Grey ES, and Sandstone ES membranes provide exceptional reflectivity and emissivity for energy savings.

JM Vapor Barrier SA

Tri-laminate woven polyethylene, nonslip, UV-protected top surface provides temporary weather protection for 90 days. Provides high tensile strength and puncture resistance.

Self-sealing, high-quality SBS rubber and asphalt blend provides low air and vapor permeability.

Silicone release film allows for ease of self-adhering installation.

Installation Supplies

Johns Manville supplies a full range of necessities for PVC system installation and maintenance, including:

- JM PVC Accessories

- Adhesives, Cleaners and Primers

- Fasteners and Plates

- Insulation and Cover Boards