Johns Manville EPDM Systems

Durable. Flexible. Smart.

With superior durability and flexibility, EPDM is a smart roofing solution.

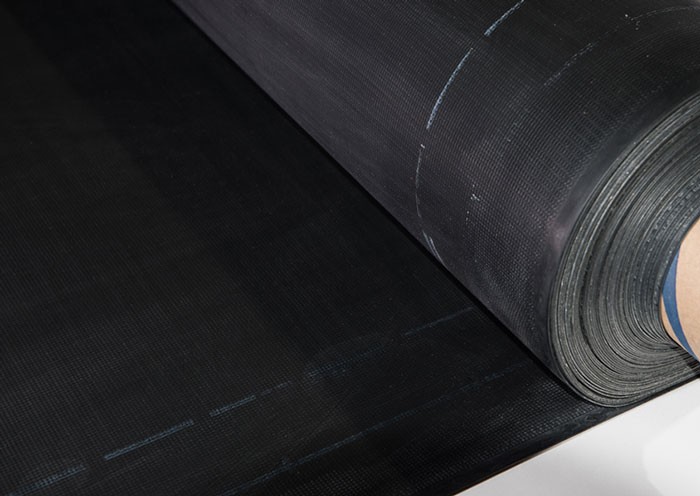

Johns Manville's EPDM production facility is one of the world's most technologically advanced, allowing them to extrude its sheets instead of using the traditional calendering process.

JM's EPDM is manufactured thicker with a more uniform surface finish. This advancement in manufacturing cleaner sheets requires less preparation to ensure a stronger bond during installation.

JM EPDM NR

Vulcanization Process: Combines two layers of membrane to produce a fully cross-linked monolithic membrane.

Membrane Formulation: Performs in extreme temperature climates and withstands differential movement (elongation).

UV-Stabilization Properties: Offers outstanding ozone and weather resistance delivering one of the longest service lives available.

Technical Expertise: Backed by 30+ years of EPDM experience and installations.

JM EPDM NR FIT Systems

Meets the requirements of ASTM D 4637, Type I

Factory Inseam Tape: For superior quality assurance and labor savings compared to field fabricated seams.

Fully Extruded: Produces fewer air voids, more uniform thickness and smoother sheets.

Vulcanization Process: Combines two layers of membrane to produce a fully cross-linked monolithic membrane.

Membrane Formulation: Performs in extreme temperature climates and withstands differential movement (elongation).

UV-Stabilization Properties: Offers outstanding ozone and weather resistance delivering one of the longest service lives available.

JM EPDM R

Meets the requirements of ASTM D 4637, Type II

Fully Extruded: Produces fewer air voids, more uniform thickness and smoother sheets.

Vulcanization Process: Produces a redundant waterproofing monolithic membrane.

Polymer Formulation: Performs in extreme temperature climates and withstands differential movement.

UV-Stabilization Properties: Offers superior ozone and weather resistance delivering one of the longest service lives available.

JM EPDM R FIT Systems

Meets the requirements of ASTM D 4637, Type II

Factory Inseam Tape: For superior quality assurance and labor savings compared to field fabricated seams.

Fully Extruded: Produces fewer air voids, more uniform thickness and smoother sheets.

Vulcanization Process: Combines two layers of membrane to produce a fully cross-linked monolithic membrane.

Polymer Formulation: Performs in extreme temperature climates and withstands differential movement (elongation).

UV-Stabilization Properties: Offers outstanding ozone and weather resistance delivering one of the longest service lives available.

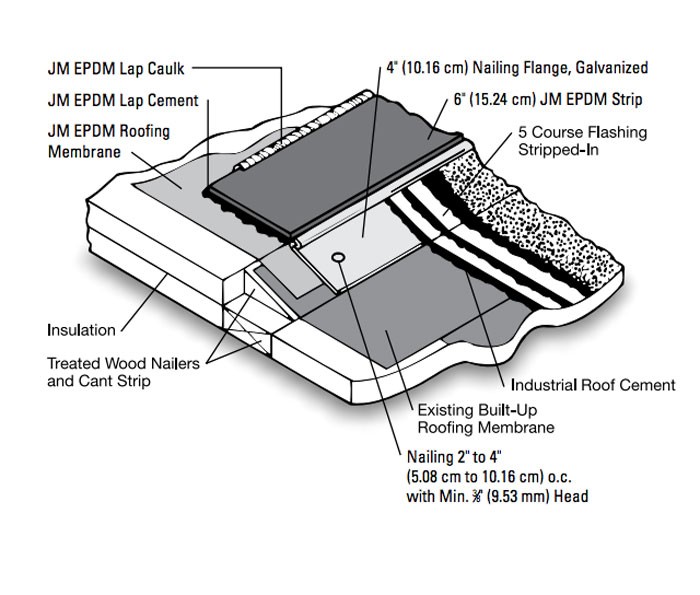

JM EPDM Metal/Membrane Flashing

JM EPDM Metal/Membrane Flashing is a specially designed and manufactured flashing for sealing and waterproofing JM EPDM roofing systems where it joins an adjacent bituminous roof membrane. It is comprised of a nominal 6" (15.24 cm) strip of JM EPDM membrane secured (using a patented method) to flanges of nominal 4" (10.16 cm) wide, Type 100G-6, galvanized steel.

JM Vapor Barrier SA

Tri-laminate woven polyethylene, nonslip, UV-protected top surface provides temporary weather protection for 90 days. Provides high tensile strength and puncture resistance.

Self-sealing, high-quality SBS rubber and asphalt blend provides low air and vapor permeability.

Silicone release film allows for ease of self-adhering installation.

Installation Supplies

Johns Manville supplies a full range of necessities for EPDM system installation and maintenance, including:

- JM EPDM Accessories

- Adhesives, Cleaners and Primers

- Fasteners and Plates

- Insulation and Coverboards